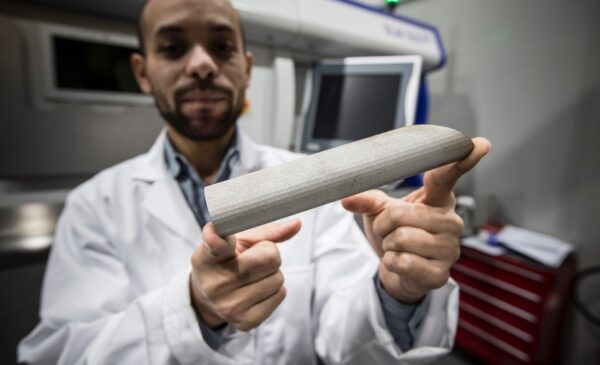

Resilient packaging for complex quantum sensors is essential in creating lightweight, high-performance technology. Professor Moataz Attallah, researcher at the UK Quantum Technology Hub Sensors and Timing, is working to create smart magnetic shielding to protect and enhance sensor technology, and is inviting the wider Hub and industry community for collaboration opportunities.

Professor Attallah has had much success particularly in the first phase of the Quantum Technology Hub, most notably the Engineering and Physical Sciences Research Council (EPSRC)-funded project QT-Shield, which aimed to create designs for quantum sensors based on magnetic shielding to eliminate magnetic interference, allowing quantum behaviour to be accurately observed. This project, which involved industry collaboration with Magnetic Shields Ltd, made ground-breaking developments in a research area where still little is known, with the results showing that the performance of 3D printed magnetic shields can exceed the performance of conventionally manufactured shields.

Magnetic shielding remains the key material for quantum sensor packaging, but Professor Attallah and his team are able to work with a range of materials including metals, plastics, ceramics and even silicon. The team, who work in the University of Birmingham’s Advanced Materials and Processing Laboratory (AMPLab) which houses a range of impressive 3D printing machines, have also reached a good level of maturity with 3D printed permalloy-80, as well as 3D printed Invar-36, a material with a low coefficient of thermal expansion. Highly sensitive devices such as quantum sensors need to be built with resilience to temperature changes and other disruptions in the external environment.

The team are keen to work with other Hub researchers and interested industry companies to build strong packaging for quantum sensor technology for small and large production scales. New materials can also be considered, and proof of concepts can be developed in as little as a few months.

For more information on the types of materials which can be used in 3D printing, read this slide.

If you would like to get in touch with Professor Moataz Attallah, you can email him directly at: [email protected].